Grill Magnet

Product Details:

- Frequency 50/60 Hz

- Voltage 220 V

- Composite Iron/Steel Housing with Magnetic Rods

- Magnet Grade N35 / N52 (Neodymium or Ferrite)

- Application Indudtrial

- Power 220 Volt (v)

- Surface Finish Polished

- Click to View more

Grill Magnet Price And Quantity

- 1 Piece

- 200.0 INR/Piece

Grill Magnet Product Specifications

- Indudtrial

- 100 kg/hr to 1000 kg/hr depending on size

- Custom sizes available from 100 mm to 1000 mm length

- Silver

- 220 Volt (v)

- Ferrous Separation

- Stainless Steel (304/316)

- Polished

- AC

- Rod

- Removes ferrous contamination from free-flowing materials in process industries

- Permanent Magnet

- 220 V

- 50/60 Hz

- Iron/Steel Housing with Magnetic Rods

- 5 kg to 25 kg (varies by model)

- Other

- N35 / N52 (Neodymium or Ferrite)

Grill Magnet Trade Information

- Cash Advance (CA), Cash in Advance (CID)

- 2 Days

- Contact us for information regarding our sample policy

- Asia

- All India

Product Description

With our hard-earned experience of this mechanical industry, we offer a vast range of Grill Magnet to our valuable clients. It is utilized in different businesses like Food, Feed, Flour, Grain, Chemical, Plastic and preparing plants to evacuate little iron particles. This item is valuable for partition of iron particles from dry, granular or powder material like Sugar, Tea, Coffee, Spices and so forth. We deliver this Grill Magnet at market leading price rate without any delay.

Other Details:

- Condition: New

- Corrosion Resistance: yes

Technical Specification

|

Outer Diameter |

300 mm |

|

Usage/Application |

Industrial |

|

Material |

Stainless Steel |

|

Magnet Grade |

N40 |

|

Brand |

Azad |

|

Surface Treatment |

Polished |

|

Packaging Type |

Box |

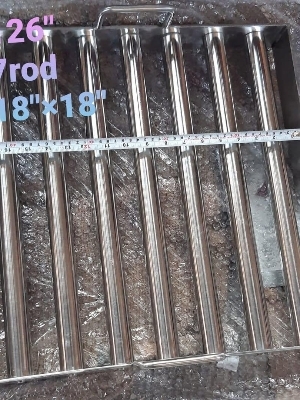

Customizable Magnetic Rods for Optimal Performance

The Grill Magnet is designed to allow customization of magnetic rodsranging from 4 to 12tailoring its ferrous separation capacity for specific industrial requirements. This flexibility enables efficient removal of contaminants from free-flowing materials, ensuring product quality and machinery protection.

Durable Construction and High Corrosion Resistance

Constructed from polished stainless steel (304/316), the Grill Magnet offers excellent durability and resists corrosioneven in aggressive industrial environments. Its robust iron/steel housing ensures a long service life, while the high-end finish maintains hygienic standards essential for processing applications.

Versatile Mounting and Easy Maintenance

Available with flange, plate, or drawer mounting, the Grill Magnet provides straightforward installation tailored to your setup. Manual or easy-clean designs simplify routine maintenance, reducing operational downtime. End connections are available in threaded or flanged variants for seamless integration.

FAQs of Grill Magnet:

Q: How does the Grill Magnet remove ferrous contamination from industrial materials?

A: The Grill Magnet uses powerful permanent magnets (N35/N52 grade) arranged in rods to attract and extract iron particles from free-flowing materials, ensuring product purity and preventing machinery wear in process industries.Q: What are the available options for mounting the Grill Magnet in an industrial setup?

A: The Grill Magnet can be installed using flange, plate, or drawer mounting options, offering adaptability to various processing lines. You can choose the mounting type that best fits your existing equipment and workflow requirements.Q: When should the Grill Magnet be cleaned, and how is the cleaning process conducted?

A: Cleaning frequency depends on contamination levels and operational hours. The magnets easy-clean, manual design allows users to periodically remove and clean the magnetic rods to maintain separation efficiency.Q: Where can the Grill Magnet be utilized within an industrial process?

A: This device is ideal for use in processing plants handling powders, granules, or free-flowing materials. Typical applications include food, chemical, mineral, and pharmaceutical industries where ferrous contamination is a concern.Q: What benefits does high magnetic intensity (up to 12000 Gauss) provide in filtering materials?

A: High magnetic intensity ensures efficient capture of even fine iron particles, enhancing overall product quality and reducing risks of equipment damage, which helps optimize production and save on maintenance costs.Q: How does the Grill Magnet support operation in corrosive environments?

A: Thanks to its stainless steel (304/316) construction and high corrosion resistance, the Grill Magnet remains effective and reliable, even when used in locations exposed to moisture or chemical vapors, extending its operational lifespan.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+