Gosh Power Magnet Plate 10000

230.0 INR/Piece

Product Details:

- Power Supply Electric

- Composite Permanent Magnet Plate

- Frequency 50 Hz

- Material Stainless Steel & Magnet

- Magnet Grade NdFeB / Ferrite

- Voltage 220 V AC

- Surface Finish Polished

- Click to View more

X

Gosh Power Magnet Plate 10000 Price And Quantity

- 1 Piece

- 230.0 INR/Piece

- Available as per requirement

- Food processing, mining, recycling, plastic, chemicals, ceramics, grain, textile industries

- High Magnetic Strength, Robust Construction, Low Maintenance

- Varies based on plate size

- Hanging or Fixed

- From 4,500 Gauss to 12,000 Gauss

- Up to 80°C

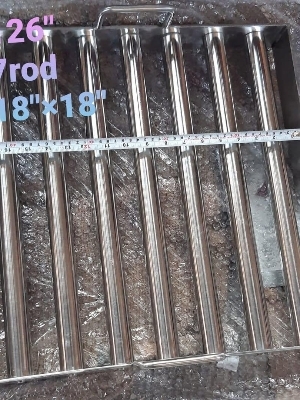

Gosh Power Magnet Plate 10000 Product Specifications

- 220 V AC

- Other

- Polished

- Industrial

- 1.5 kW

- Stainless Steel & Magnet

- Remove ferrous contaminants from products on a conveyor

- 45 Kg (approx.)

- steel

- Other

- NdFeB / Ferrite

- 50 Hz

- Customized

- 10000 Gauss

- 300 mm x 300 mm to 1200 mm x 1500 mm

- Magnets

- Electric

- Permanent Magnet Plate

- Available as per requirement

- Food processing, mining, recycling, plastic, chemicals, ceramics, grain, textile industries

- High Magnetic Strength, Robust Construction, Low Maintenance

- Varies based on plate size

- Hanging or Fixed

- From 4,500 Gauss to 12,000 Gauss

- Up to 80°C

Gosh Power Magnet Plate 10000 Trade Information

- Cash Advance (CA), Cash in Advance (CID)

- 10 Piece Per Day

- 3 Days

- Contact us for information regarding our sample policy

- Asia

- North India

Product Description

Magnetic Plates are important industrial iron separators that are used for the separation of fine ferrous materials and tramp iron from many types of free flowing and pneumatically conveyed material like corn sugar flour gravel plastic and others granular materials.High-Strength Magnetic Separation

With a magnetic surface strength of up to 12,000 Gauss, the Gosh Power Magnet Plate 10000 excels at extracting ferrous particles from industrial product flows. Its reliable lifting capacity and adaptable design make it a compelling solution for facilities requiring effective metal separation. Robust construction ensures consistent performance even under strenuous operational conditions.

Custom-Built to Fit Your Process

Available in a wide range of sizes and shapes, the Gosh Power Magnet Plate 10000 can be tailored to your unique conveyor specifications and material handling challenges. From small food processing lines to large-scale mining operations, customization ensures optimal separation efficiency and seamless integration.

Versatile Applications Across Industries

This magnetic plate serves various sectors, including food, chemicals, plastics, textiles, ceramics, grain, and recycling. Its ability to safeguard downstream equipment and enhance product quality by eliminating iron contaminants makes it an essential asset for diverse industrial applications.

FAQs of Gosh Power Magnet Plate 10000:

Q: How does the Gosh Power Magnet Plate 10000 operate to remove ferrous contaminants?

A: The Gosh Power Magnet Plate 10000 employs high-strength permanent magnets to attract and capture ferrous particles as material flows over or near its surface, effectively removing contaminants and protecting downstream equipment.Q: What are the key installation options for the magnetic plate?

A: You can mount the magnet plate either as a hanging unit above a conveyor or as a fixed component, depending on your process requirements and available space.Q: When should I consider using a customized plate size or shape?

A: Customized sizes or shapes are ideal when standard plates do not perfectly fit your conveyor dimensions or material flow patterns, ensuring maximum magnetic separation efficiency for your specific application.Q: Where is the Gosh Power Magnet Plate 10000 commonly used?

A: This magnetic separator is widely used in food processing, mining, recycling, plastics, chemicals, ceramics, grain, and textile industries across India and industrial sectors requiring reliable removal of iron contaminants.Q: What is the process for supplying power to the magnet plate?

A: The unit requires a 220 V AC power connection at 50 Hz and consumes approximately 1.5 kW. Ensure proper electrical installation for safe and efficient operation.Q: How does using this magnet plate benefit my industrial process?

A: Utilizing the Gosh Power Magnet Plate 10000 helps prevent equipment breakdowns, maintains product purity, reduces maintenance costs, and supports compliance with safety standards by effectively removing ferrous contaminants from product streams.Q: What maintenance does the magnet plate require?

A: Thanks to its robust stainless steel construction and permanent magnet design, the plate is low-maintenance, typically needing only periodic cleaning to remove collected contamination from the magnetic surface.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email